Experimental Analysis of a Bicycle Frame

Background & Motivation

Some of the best bike frames are custom made.

Smaller custom frame builders may not have the equipment to properly test their frames.

The mission: test the durability of a custom bike frame using ISO standards.

The frame tested belongs to professor Steve McGuire — a titanium adventure fat tire bike.

Experimental Methods

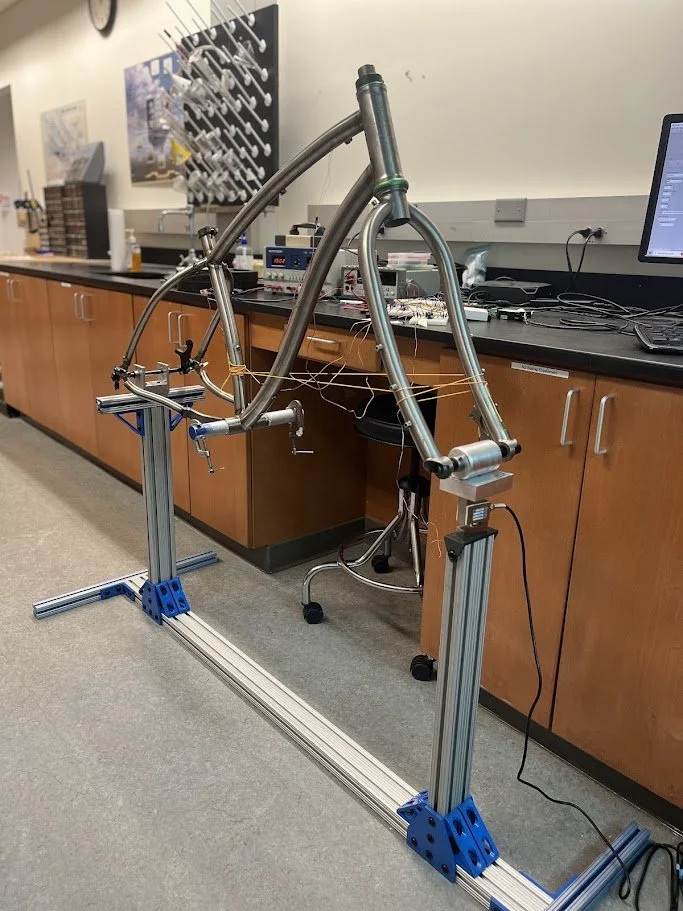

Testing followed ISO 4210 Impact Test Standard to measure stress and strain in key locations.

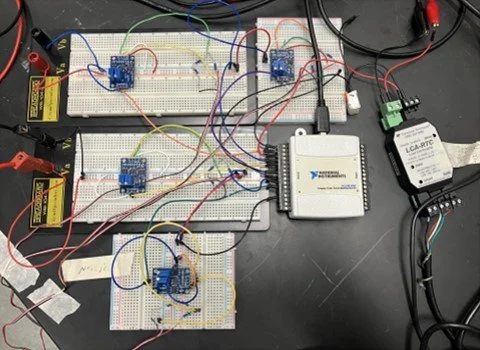

Instruments used:

4x strain gauges

4x AD 620 voltage amplifiers

STC 500 lb. load cell

LCA - RTC load cell amplifier

NI USB-6008 DAQ card

Testing rig assembled from 20x40 aluminum extrusions

Drop height: 200mm

Full load test mass: 95.8kg

Experimental Setup

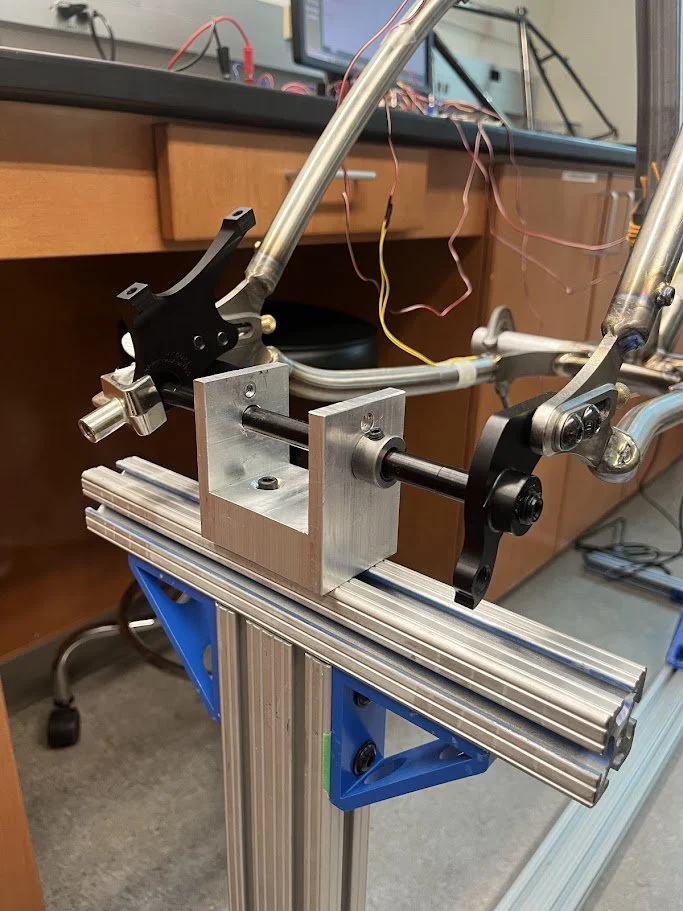

Rear Hinge Mount

Load Cell Mount & Roller

Bracket to Elevate Bike

Running the Test

Weight Mounting

Strain Gauge Amplifier Circuit & DAQ System

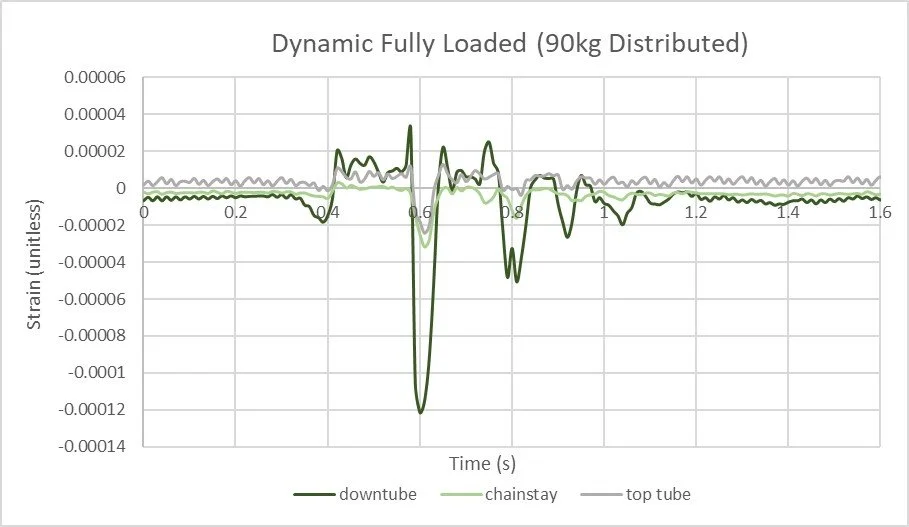

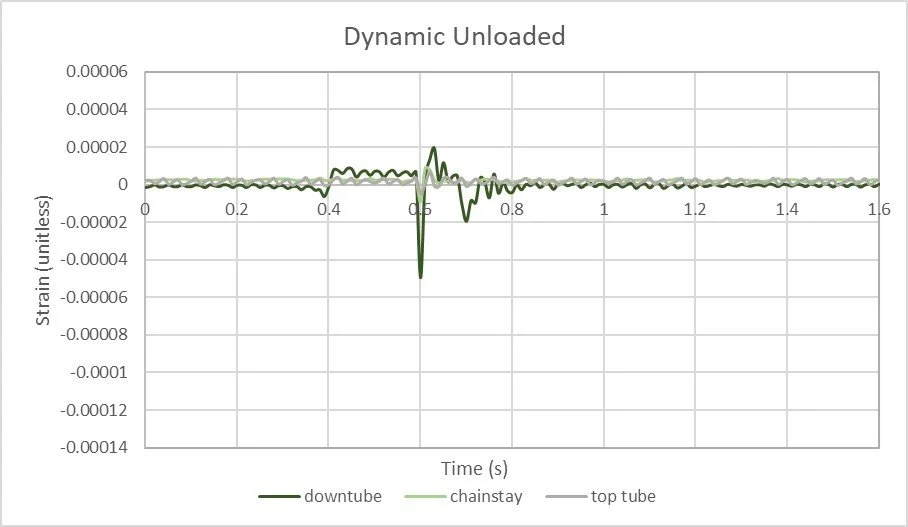

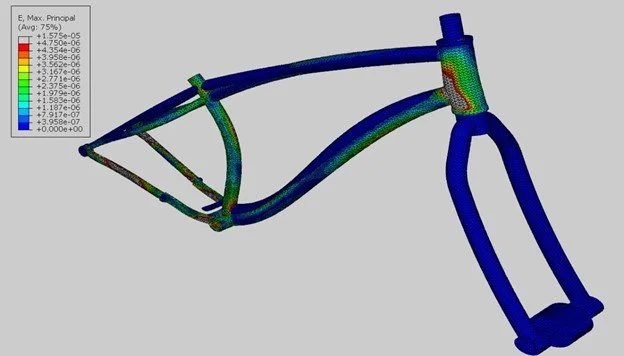

Results and Conclusions

Static strain and force of a loaded bike frame. Compared to FEA (computer generated) results.

Fully loaded mass = 95.8kg

The most strain and elongation was observed on the downtube.

The highest observed strain was 120.1µε — within the elastic region of 3A-2.5V titanium.