Titanium Bicycles

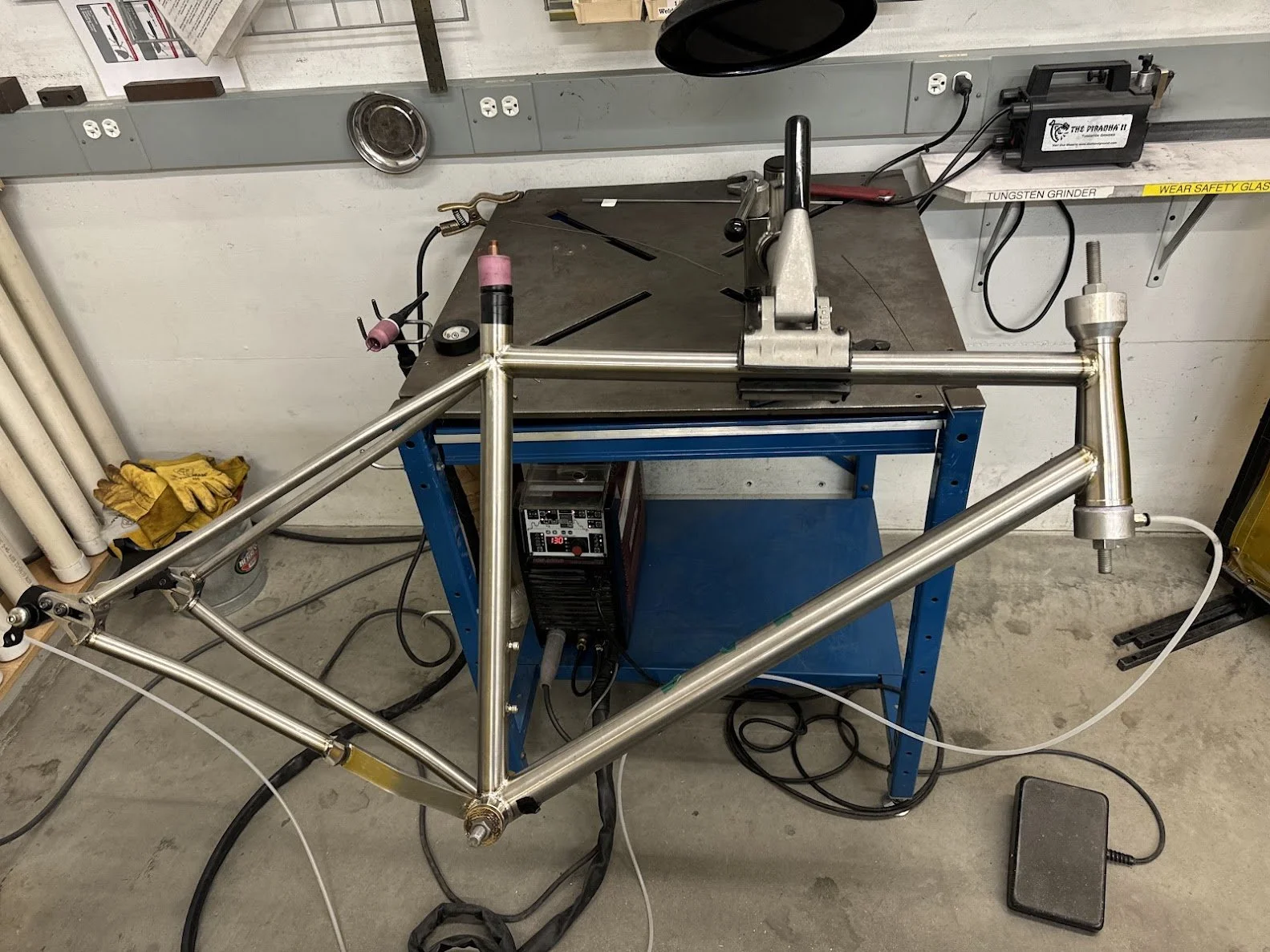

One of the greatest opportunities I had at the University of Iowa was the chance to take Hand Built Bike — a class where students are taught how to design and fabricate bicycle frames. Through the class, I learned how to TIG weld, use machinery, and apply my engineering skills to a design process. I had the privilege to take the class three times where I made six unique bicycle frames. Although my first frames were made out of steel, titanium’s flexibility, durability, and lightweight properties make it my favorite material for bicycle frames. Therefore, most of the frames I have made were titanium frames. These are my titanium creations.

The Scallion Pancake

This was the second frame I designed and built. I wanted to treat this frame as if it were the last frame I made. In other words, I wanted to go all out with this design. Inspired by the bike made and ridden by my TA, I wanted to attempt a double top tube design.

The idea: a hardcore titanium hardtail that blends form and function

To make this a proper hardcore hardtail, I gave the bike a 65 degree head tube angle and tall bottom bracket — this makes the bike maneuverable and playful. To blend form with function, I decided on a split top-tube design with a cross member in the main triangle to provide support and aesthetic.

The Randcruiser

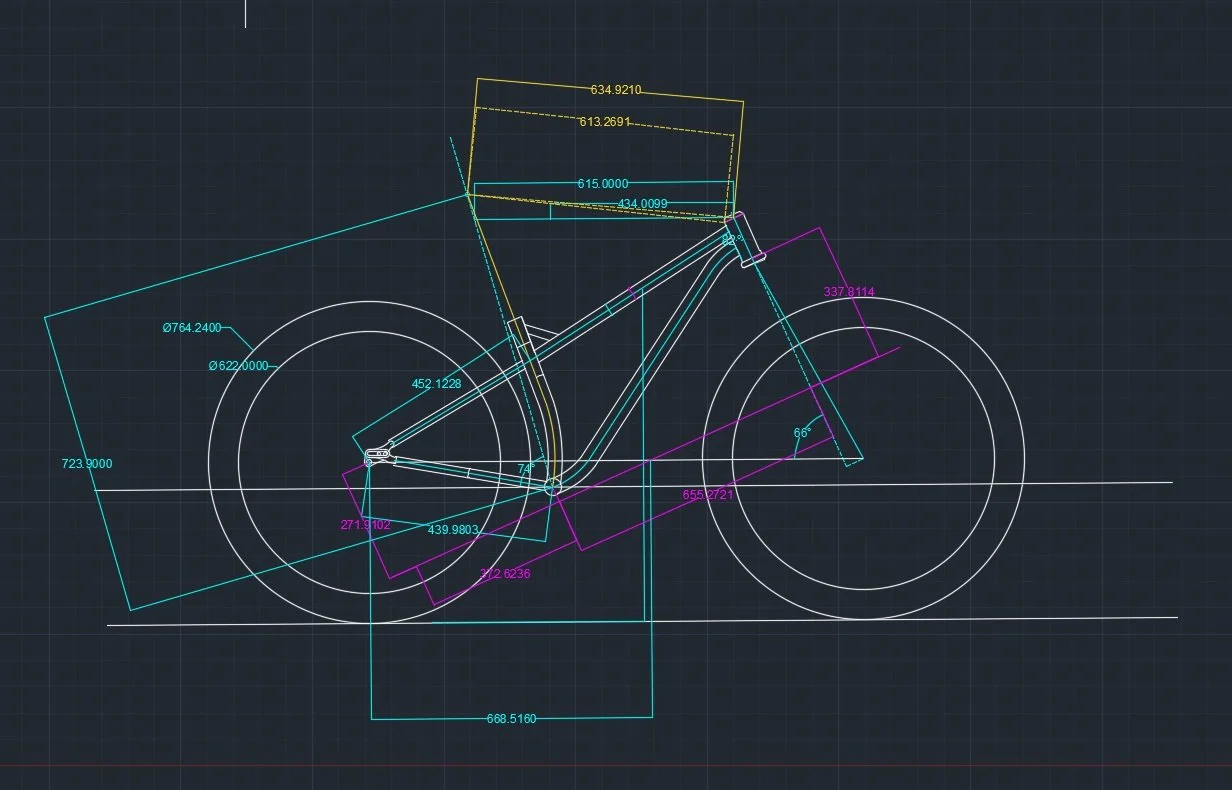

This bike was specifically made for a client. This client had a 90s Cannondale mountain bike that they fell in love with, and wanted a modern version of that bike. Specifically they asked for a hardtail mountain bike with 130mm of front suspension travel, mounts for disc brakes, and internal cable routing (which I had never done before). The name of the bike is a play on my client’s name, Randy.

The idea: a modern take on an old school mountain bike.

I gave this bike short 440mm chain stays to make to make it snappy and playful like my client’s old Cannondale. To modernize the geometry, the bike was given a 66.5 degree head tube angle and clearance for 29x2.8” tires. I based the reach off of my client’s other mountain bike.

Prior to sandblasting the frame, I anodized a small portion of the chain stays blue before covering them with a vinyl sticker with bike’s name, Randcruiser. After sandblasting, I removed the sticker to reveal the blue anodized lettering.

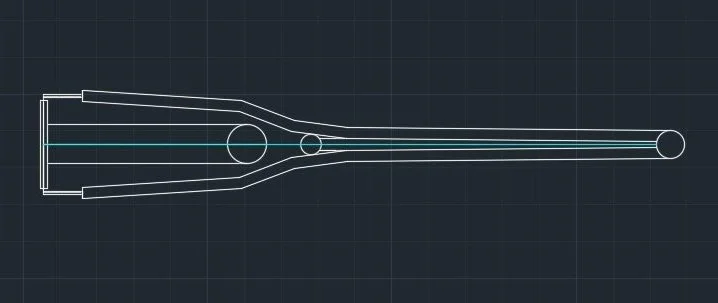

To create internal routing ports, I grinded down 0.3130” OD tubing on an angle grinder. I then drilled into the down tube (pictured above) and welded on the ports. I cut them down to size on the manual mill.

The McCrispy

This was the final frame that I made as a student at the University of Iowa. For my final frame as a student, I wanted to pay tribute to my professor Steve McGuire — who has a penchant for bendy titanium fat bikes. I wanted this fat bike to be an extension of my own style too. To do so, I wanted the bike to feel less like a fat bike, and more like a mountain bike with fat tires. The name “McCrispy” comes from a nickname given to me by Professor McGuire during a trip to Dresden, Germany.

The idea: a fat tire bike with mountain bike geometry and round swooping design language.

To be able to clear a 4.8” tire without interfering with the chainring or crank, I made a yoke from titanium plate. This was my first time making a bike with a yoke.

I designed this bike to have a dramatic S-curve on the downtube and a steep seat tube curve. The top tube has a shallow curve to match the rest of the tubes. I gave the bike 455mm chain stays and a 69 degree head tube angle to make the bike feel like a mountain bike.

I gave the bike an internal routing port on the seat tube to have the ability to run a dropper seat post. I did this using the same process as the internal routing ports on the Randcruiser.

The Gravel Panther

The idea for the Gravel Panther came from an issue I took with many modern gravel bikes: the chain stays are too short resulting in a less stable bike. My goal was to create a gravel geometry that was both stable and playful. I knew right off the bat that I wanted this bike to be finished with a leopard print because of my love for animal prints. As I was brainstorming what color to anodize the frame, the name Gravel Panther jumped right at me — a pink anodized bike with the name Gravel Panther.

The idea: a pink gravel bike that is both playful and stable.

To achieve a leopard print finish, I printed a custom vinyl pattern in Illustrator. I polished the frame and applied the vinyl pattern before sand blasting the frame with a fine media. Afterwards I anodized the frame pink with a gold fade.

To accomplish this goal, I gave the bike long 460mm chain stays. To keep the bike feeling playful, I gave it a 70mm bottom bracket drop (distance from axle to bottom bracket). The idea was that a taller bottom bracket will raise the center of gravity and give the bike more front end control.

I designed a half yoke using titanium plate. This allowed for both tire clearance and chainring clearance.